Concrete blocks are an essential building material in the construction industry, providing strength, durability, and adaptivity. Concrete blocks are also known as concrete bricks, cement blocks, or cement bricks. In Karnataka, India, where construction activities are booming, the use of cement blocks is also increasing due to their flexibility to meet diverse structural needs, low cost, and ease of installation. In this article, we will look into different types of construction blocks in India.

Types of Construction Blocks

-

Solid Concrete Blocks

-

Hollow Concrete Blocks

-

AAC (Autoclave Aerated Concrete) Blocks

-

Fly Ash Concrete Blocks

-

Interlocking Concrete Blocks

-

Decorative Concrete Blocks

Solid Concrete Blocks:

Solid concrete blocks are a type of concrete block used in construction. They are made from a mixture of cement, aggregates, and water. While not all solid concrete blocks are fully solid, they are more solid than hollow blocks. Solid concrete blocks are used for projects like paving, where stability and durability are essential, and for load-bearing walls, retaining walls, and other structural applications. These solid blocks are available in different shapes and sizes, and their strength and durability make them a popular choice for modern building design and construction.

Hollow Concrete Blocks:

Hollow concrete blocks are lightweight masonry blocks made of concrete that contain hollow cores within their structure. These blocks are used in construction for various purposes, such as building walls, retaining walls, and decorative elements. Hollow concrete blocks are lighter, easier to handle, and more economical than solid concrete blocks. They are also more flexible in design, allowing for a wide range of architectural applications. The hollow spaces within the blocks can be used to run electrical wiring, piping, and reinforcement bars for added strength. Hollow concrete blocks are available in different sizes and shapes, such as stretcher, pillar, and lintel blocks. They are also used in load-bearing walls, retaining walls, and as sound barriers.

Hollow concrete blocks are a versatile and cost-effective construction material that has been used for hundreds of years. They continue to be a popular choice for modern building design and construction. Hollow blocks are widely used in residential and commercial buildings, as well as for partition walls and infill panels.

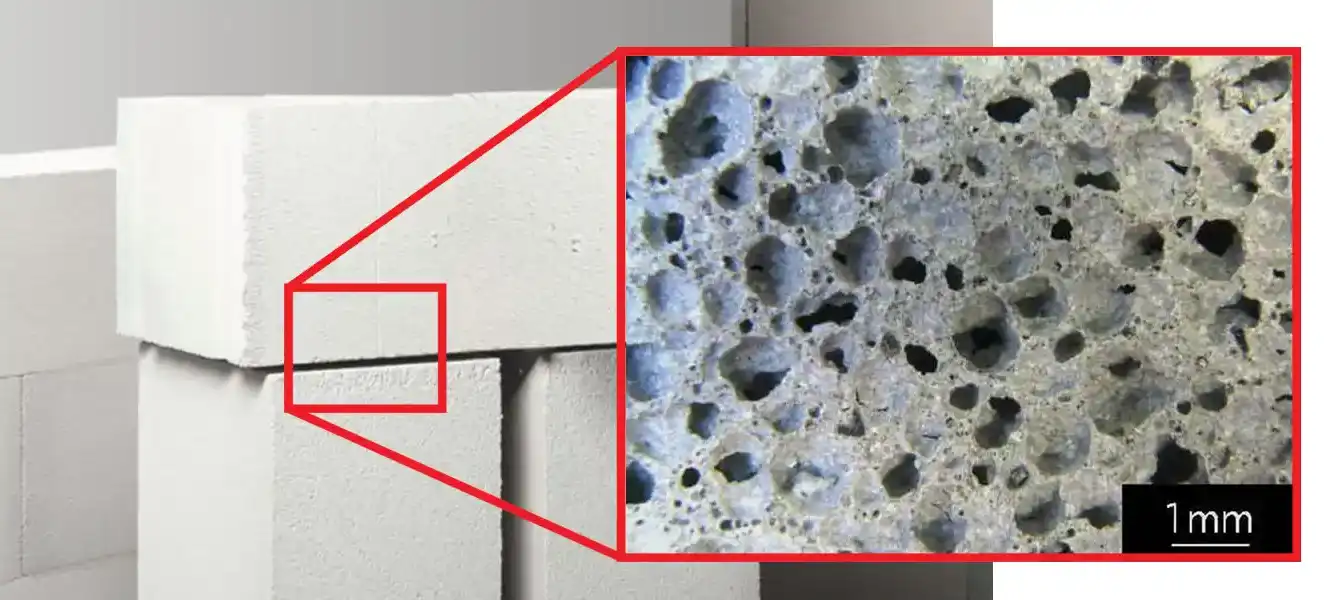

AAC (Autoclave Aerated Concrete) Blocks:

Autoclaved aerated concrete (AAC) blocks are a type of lightweight, precast, cellular concrete building material that offers insulation, fire resistance, and mold resistance. AAC blocks are composed of quartz sand, calcined gypsum, lime, portland cement, water, and aluminum powder. They are cured under heat and pressure in an autoclave, which results in a material with millions of tiny air cells, giving it an insulation value of R-8. AAC blocks are available in various shapes and sizes, including panels, blocks, and specialty shapes. They are used in construction for walls, floors, and roofs, and they are particularly suitable for high-rise buildings and those with high-temperature variations. AAC blocks are less dense than traditional concrete blocks, which makes them easier to handle and install, but they also have lower structural compression strength, requiring reinforcement in load-bearing applications.

Fly Ash Concrete Blocks:

Fly ash blocks, also known as fly ash bricks, are building materials used as masonry units. They are made from a mixture of fly ash, water, quicklime or lime sludge, cement, aluminum powder, and gypsum. These bricks are manufactured by compressing the mixture at high pressure and then curing it in a steam bath. They are known for their strength, durability, and resistance to fire, and they are lighter and stronger than traditional clay bricks. Fly ash bricks are considered an environmentally friendly alternative to clay bricks, as they are made from a byproduct of coal-fired power plants, which helps in the conservation of natural resources and the protection of the environment. They are also cost-effective and offer benefits such as high fire resistance, reduced transportation breakage, and uniform size, leading to increased durability. The primary constituents of fly ash bricks are fly ash, sand or stone dust, lime, gypsum, and a bonding agent. The properties of fly ash bricks include a smooth appearance, high thermal conductivity, good sound insulation, resistance to fire and vermin, and high durability with low moisture absorption. Fly ash bricks are widely used in construction as a substitute for traditional clay bricks due to their numerous advantages.

Interlocking Concrete Blocks:

Interlocking blocks have a unique design that allows blocks to be assembled like puzzle pieces, eliminating the requirement for mortar during construction. These interlocking concrete blocks are engineered with specialized shapes and grooves that allow the blocks to interlock with the neighboring blocks, providing stability and structural integrity to the construction. Interlocking concrete blocks are extensively used in the construction of retaining walls, roadside embankments, and terraced landscapes, and these blocks serve as effective barriers and embankments to divert water flow and create temporary dams. Moreover, they find utility as site barriers and temporary walls in construction sites, roadworks, and event venues, and security with their quick assembly and disassembly capabilities.

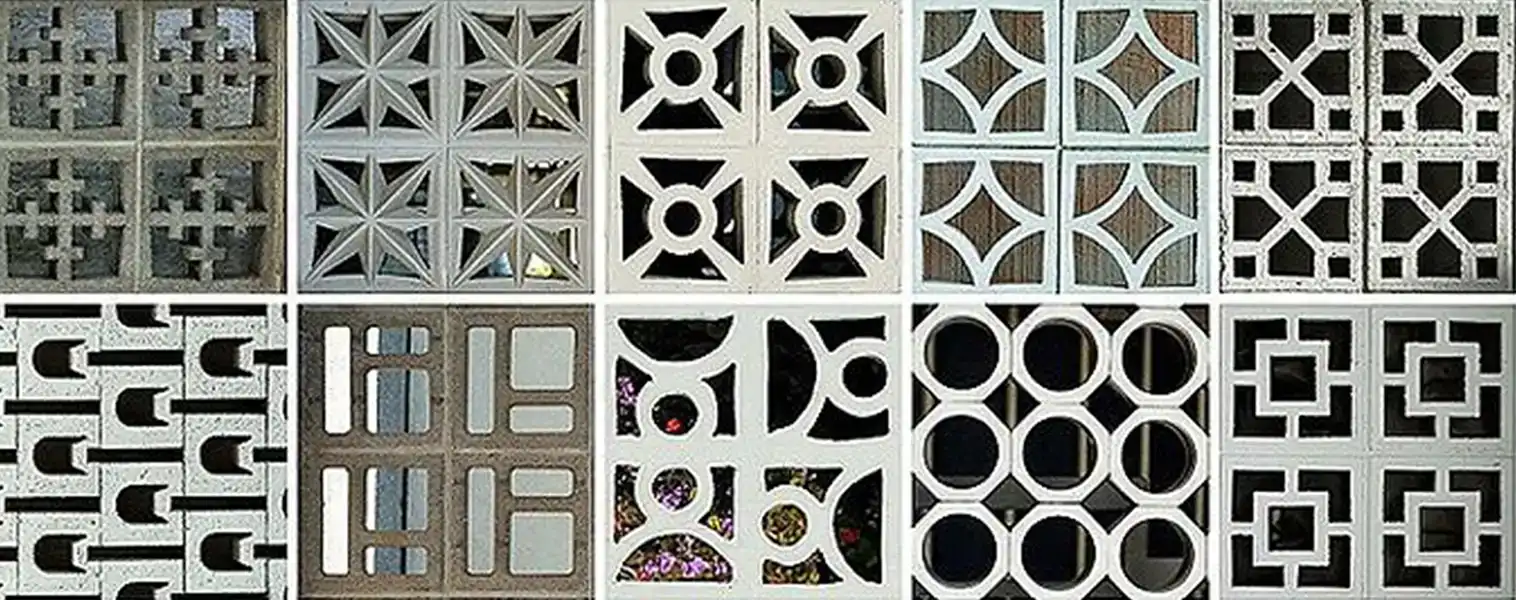

Decorative Concrete Blocks:

Decorative concrete blocks are a creative and functional solution in architectural design, providing both aesthetic appeal and practicality. These blocks come in a diverse range of shapes, sizes, and patterns, providing architects and designers with versatile designs to enhance building facades, interior spaces, and outdoor surroundings. Decorative concrete blocks transform ordinary walls into visually interesting structures by adding character with intricate designs and textures. Moreover, besides their decorative value, these blocks offer practical benefits such as natural ventilation, light dispersion, and privacy screening, making them a versatile choice for improving the livability and aesthetics of building environments. From historic buildings to contemporary structures, commercial buildings, or public spaces, decorative concrete blocks continue to inspire innovative design solutions and elevate the visual appeal of architectural projects.

In conclusion, the use of concrete bricks in construction in India is broad and multidimensional, with various types of blocks catering to different structural and design needs. Concrete blocks remain a popular option among builders and developers across the country, no matter if it’s for load-bearing walls, thermal insulation, or decorative purposes. Concrete blocks continue to contribute to the growth and development of the construction industry across the country.