What is sand?

Sand is a granular material composed of small and fine grains, including various materials, minerals, and rocks. The particle size of sand ranges from 0.06mm to 2mm.

Why is Sand Important in Construction?

Sand is essential in construction for building strong, long-lasting, and visually appealing structures and infrastructure. Let's have a deeper look into the following factors:

-

Sand is an essential component in creating concrete, as it gives strength and bulk to the mixture.

-

Sands with certain qualities are used for brickwork, block laying, and plastering to ensure durability and cohesion.

-

Sand is a base material for a sturdy foundation capable of bearing weight and resisting movement or settling.

-

Sand is used in landscaping to level terrain, improve walkways, and improve drainage techniques.

What are the Different Types of Sand Used in Construction?

Each type of sand has unique qualities, benefits, and drawbacks. In this section, we will discuss each type of sand in detail.

-

River Sand

-

M-Sand

-

P-Sand

-

C-Sand

-

Filter Sand

-

Bedding Sand

River Sand

River sand is a finely graded, granular material composed of minerals and rocks. The river sand is composed of minerals and rocks. The grains of river sand are generally rounded and smooth, resulting from the constant abrasion caused by water and other sediments.

Properties of River Sand:

Well-rounded grains: River sand often contains rounded grains because of natural weathering and erosion processes.

Acceptable to Medium Grain Size: River sand ranges between 0.0625mm and 2mm.

Good Binding Qualities: River sand minerals like silica give good bonding strength to construction materials.

Pros of River Sand:

-

River sand is widely accessible for construction projects and is widely available in many areas.

-

Its rounded grains make it easier to work with, so it's suited for various building purposes.

-

River sand helps concrete structures be more durable and generally stable.

Cons of River Sand:

-

Environmental issues: Excessive sand mining from riverbeds can cause erosion and environmental deterioration, harming river ecosystems.

-

The quality of river sand might vary based on its location and source, which can cause irregularities in its characteristics.

Also, you can go through the article written on Difference Between P sand and M sand.

What is Manufacturing Sand:

M Sand is made by crushing rocks or quarry stones, and it is commonly known as manufactured sand. However, although M-Sand is widely available on the market, it is not preferred for construction because of its drawbacks.

Pros of M Sand:

M sand occasionally costs slightly more than river sand because of the manufacturing process.

Note: Read this article to know more about M Sand Vs River Sand.

Cons of Manufacturing Sand

M sand’s quality and consistency can change depending on the manufacturing process and raw materials. Impurities and uneven particle sizes affect the concrete mixes' strength and toughness.

M sand may have a larger angular form than river sand or concrete sand, impacting workability during construction. More water or chemical additives may be needed to reach the desired consistency, which could affect the entire construction process.

The Presence of Silt: Most people are unaware of what silt is. Fines are present in m sand because M sand is produced by crushing rocks to the required particle size. Fines, which are tiny particles that can impair the workability, cohesion, and general strength of the concrete or mortar mix, can be produced in substantial quantities due to this operation.

If you are planning to buy M Sand, we recommend you check out this article on buying guide on M Sand.

What is Plastering Sand?

Plastering sand, also known as P sand, is a finely-grained sand that undergoes a washing process to eliminate any silt, salt, or clay particles. This ensures a smooth finish and minimizes cracking and shrinking during drying. Plastering sand is versatile, serving both internal and external plastering and rendering purposes. Its smooth and rounded grains have no sharp edges, contributing to its excellent performance in construction applications.

Properties of P Sand

-

Grain size, medium to coarse: The particles in plastering sand normally range from 0.25 mm to 2.36 mm.

-

Angular grains: They have angular particles, which improve adhesion and interlocking.

Pros of P sand

-

Enhancing workability: Because of its larger grain size and outstanding workability, sand is a popular choice for masonry and plastering projects.

-

Strengthened bond: The angular particles strengthen the bond between the sand and the surface of the plaster or masonry.

Cons of Plastering Sand:

-

Accessibility: In some areas, sand might not be as accessible as river sand or M sand, necessitating cautious procurement.

-

Requirement for sieving: Sand must be sieved before usage to eliminate larger particles, adding another step to the construction process.

Note: Click here to learn more about what is plastering sand.

What is Concrete Sand?

Concrete sand, commonly referred to as C sand, is a sand variant produced by crushing the quarried stone to achieve a particle size that completely passes through a 0.15 mm–4.75 mm sieve. This type of sand provides consistent quality, enhanced workability, and a reduced environmental impact compared to river sand.

Properties of Concrete Sand

Size of coarse grain: Larger grains make up C sand, which typically has diameters between 0.15 mm and 4.75 mm.

Pros of C Sand (Coarse Sand) in Construction:

-

Construction projects benefit significantly from the strength and stability that concrete sand offers. It is frequently utilized as a base material for roads, walkways, and foundations since it has a solid load-bearing capability.

-

Cost-effective: Concrete sand is frequently less expensive than finer or speciality sands. It is a sensible option for sizable building projects that need a sizable amount of sand due to its availability and lower cost.

-

Construction layers can be correctly compressed to the required density since C sand is so easy to compact. Proper compaction reduces the chance of settling and ensures stability.

Note: Click here to learn more about what is concrete sand.

What is Filter Sand:

Sand used in swimming pool filters and water filtration systems is known as "filter sand." It has the following characteristics:

Properties of Filter Sand:

Filter sand comprises fine granules typically between 0.25 mm and 0.5 mm in diameter.

High silica content: It has a high silica content, enabling effective filtering.

Pros of Filter Sand:

-

Filter sand effectively removes particles and pollutants from water, ensuring a clean and secure water supply.

-

Chemical resistance: It strongly resists chemical deterioration, maintaining its filtering efficiency over time.

Cons of Filter Sand:

-

Limited use: Filter Sand's applicability for other construction uses may be restricted because it is primarily utilized for water filtering systems.

-

Specific usage: To guarantee the best filtration performance, the choice of filter Sand should follow certain norms and recommendations.

Note: Click here to know more about Moisture Content of Sand.

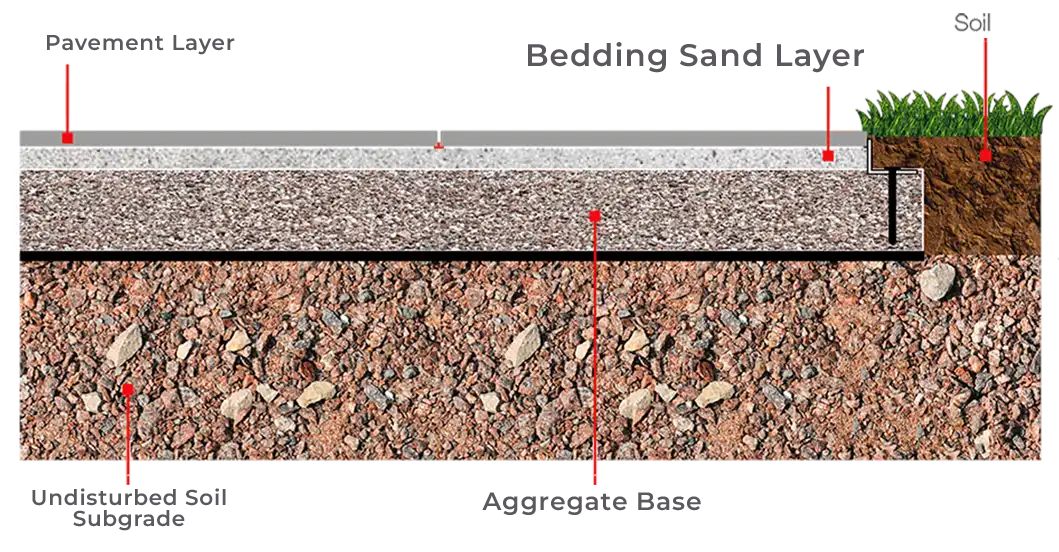

What is Bedding Sand:

Sand for bedding, sometimes called base or trench sand, is frequently used as a building material's foundation. It has the following characteristics:

Properties of Bedding Sand:

Medium to coarse grain size: The diameter of the grains in bedding sand ranges from 0.25 mm to 2 mm.

Good compaction: It is easily compatible and makes a sturdy base.

Pros of Bedding Sand:

-

Bedding Sand ensures even load distribution and prevents settling or movement, providing structures with a secure foundation.

-

Water drainage is made possible by the material's porous nature, which helps avoid water logging and related problems.

Cons of Bedding Sand:

-

Limited uses: Bedding sand is often utilized for limited uses, like pipe bedding and building road bases.

-

The use of bedding sand requires proper compaction to obtain the requisite stability and load-bearing capability.

Conclusion

Making wise judgments in building projects requires understanding the characteristics, benefits, and drawbacks of different varieties of sand. Each sand has distinctive qualities that make it suitable for particular uses. Construction experts may select the best sand type to ensure successful and long-lasting construction results by considering grain size, shape, availability, and essential qualities.

Frequently Asked Questions:

What are Coarse and Fine Sands?

Coarse sand is nothing but a particle having a diameter in the range of 0.5 mm to 1 mm, whereas fine sand is nothing but a particle having a diameter in the range of fine sand.

What is Bulking of a Sand?

An increase in the volume of sand due to an increase in the water content is called the bulking of sand.

Which is the most suitable sand for construction in Bangalore?

Alpha C Sand is the most suitable sand for construction because of its properties and functionalities.